Smart Manufacturing

- Home

- Solutions

- Smart Manufacturing

Traditionally, the purpose of manufacturing is to increase productivity and to reduce labor-related costs. In the transformation of modern manufacturing, the focus becomes in efficiency, quality and provides production-related information to operators and management center in real-time. With the rapid development of industrial automation, many factories already have prototypes of smart manufacturing, but digitalization is only an initial part of smart manufacturing, it must include centralized management and intelligent monitoring with algorithm to integrate the raw data collected from each terminal for data analysis and to improve overall production performance. Portwell has a lot of relevant expertise in smart manufacturing applications, and we provide technical consultation on product and services for manufacturing developers, accelerate the development of industry 4.0 and phase in IoT and AI into smart manufacturing.

Features

Portwell is involved in industrial automation processes in different industries, such as CNC, textile machine, inspection machine, and factory improvement, we work with customers onsite to check issues, real time status, and provide accurate solutions. We create industrial design criteria to meet specific target solutions and to match the industry requirements. In general, Portwell industrial solution will cover the features below:

Customization

Customers request will be very different, some limited in small space constraints, some request specific regulation, some customers need special input voltage, we will customize accordingly.

Diversity Device Control

Portwell smart manufacturing solution connects with different devices through diversity interface such as POE, CAN bus, and COM port. We also discussed with customers to reserve an expansion slot for future upgrades.

IP65

Waterproof and dustproof will be very different in various industries, most of the smart manufacturing developer request for IP65, and some customer request for PCB conformal coating

Anti Shock & Vibration

The machine will vibrate while operation, anti-shock and vibration is a standard in Portwell smart manufacturing solution, we design anti-shock and Vibration from connectors, cables, memory, storage all the way to system level.

Wide Temp Range

Portwell smart manufacturing solution design with a wide temperature range from -40 to 70 degrees Celsius to meet the requirement of different situation, and to make sure the systems runs stable in all demanding environmental conditions.

Fan-Less System

We have to keep system performance in a harsh and windless environment, the fan-less design is the basic standard in Portwell smart manufacturing solution.

Successful Stories

CNC

Factory Test Tool Add-on Card Factory

Automatic Yarn Winding Machine

Automatic Optical Inspection

Successful Stories

CNC

Factory Test Tool Add-on Card Factory

Textile Industry Automatic Yarn Winding Machine

Automatic Optical Inspection

Our Products

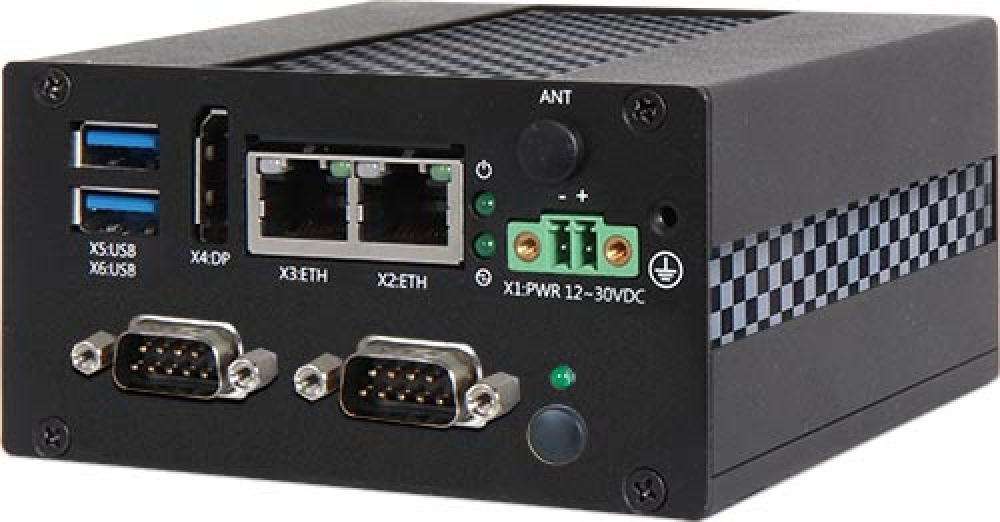

LYNX-612G

- Intel® Celeron® Processor

- Support 2x LAN and 1x M.2 for wireless module

- Extended I/O interface of 2x RS-232, 4x USB2.0

- Heavy Industry EMC standard

- Support customized appearance (Optional)

- Support extended temperature (Optional)

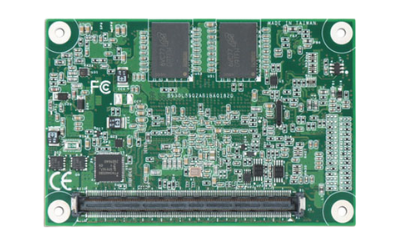

PCOM-BA01

- COM Express Rev3.0 Mini Type 10

- Intel® Atom™ E3900 Series ultra low power processor

- 1 DDI, LVDS/eDP display interface

- 4K resolution (*HDMI 3840×2160 @30Hz)

- Support eMMC storage (Option)

- Support -40°C to +80°C wide temperature

WEBS-35C3

- Intel® Core™ i High performance Fan-less Embedded Box PC

- 6th Generation Intel® Skylake-S Core™ i3/i5/i7 Desktop processor (Quad-Core CPU supported)

- Dual UB-DIMM DDR4 up to 32GB

- 2x 2.5″ SATA HDD/SSD, 1x mSATA

- Rich I/O is good for versatile applications

- 1x M.2 socket, 1x Full-size Mini-PCIe socket

- Different add-on card expansion options

LEAD-PPC-2150-B

- intel® Apollo Lake x5-E3930 Processor

- 8GB DDR3L/1600 SO-DIMM

- 128G TLC mSATA

- 10-Points Projective Capacitive Multi-Touch

- 2 x 3W speaker

- 2 x USB 3.0, 1 x HDMI, 2 x GbE

- 1 x COM for RS-232/422/485 Support

- Windows 10 IoT, Android 6.0, Linux Ubuntu™ 16.10