Industrial Automation

- Home

- Solutions

- Industrial Automation

Portwell drives the innovation behind factory automation, from robotization of labor, IIOT control and communication, to AOI machine vision imaging analysis that reduce production loss and increase overall efficiency. With the evolution of time and the relentless pursuit, we are finally closer to reaching Industrial 4.0 than at any time in history. As our lifestyle becomes more and more intelligent, the way people manufacture should also keep pace. Intelligent data communication has become an indispensable core in creating an automated factory.

The ability to interconnect machine to machine (M2M) and to harness all data into a single HMI management console in real-time is today’s challenge in cloud-based management control systems. The important decisions must be computed on the spot, and the extracted metadata is transferred back to the cloud for feedback into the system for productivity optimization. This mode of operation is the best example of Portwell’s Edge Computing.

The ability to interconnect machine to machine (M2M) and to harness all data into a single HMI management console in real-time is today’s challenge in cloud-based management control systems. The important decisions must be computed on the spot, and the extracted metadata is transferred back to the cloud for feedback into the system for productivity optimization. This mode of operation is the best example of Portwell’s Edge Computing.

Features

Communication

Intelligent communication is the backbone of factory automation which drives innovation in Industry 4.0.

Computing Power

The collaboration between machines, systems, and personnel requires significant computing power especially in the edge computing architecture.

System Integration

Factory is full of machinery, control systems and personnel. To enable seamless factory floor collaboration, the ability to integrate and customize becomes critical.

Why Choose Portwell

Global leader in industrial PC market

As a global leader in embedded computing technologies, Portwell is committed to enhance product longevity and provide silicon valley engineering support. Portwell strives to help OEMs and system integrators to enable scalable and viable industrial automation solutions.

Longtime member of Intel® IoT solutions alliance

As an Associate and longtime member of the Intel® Internet of Things Solutions Alliance, Portwell is committed to incorporating the latest technologies when designing its industrial automation products and solutions.

Portwell's Extensive product portfolio

Portwell provides a wide range of product portfolio including embedded modules, single board computers (SBC), industrial systems, rackmount computers, human-machine interface (HMI) and network security appliances.

WUX-4200

- Intel® Pentium® processor N4200, Intel® Celeron® processor N3350/J3455 (codenamed Apollo Lake)

- DDR3L 1866/1600 MHz SDRAM, up to 8GB

- Dual displays via HDMI and DisplayPort

- 1x M.2 (E+A key), 1x SATA III, 1x microSD 3.0

- Support wide input voltage range from 12V to 19V

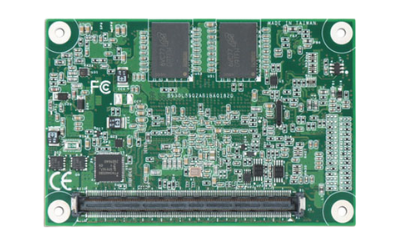

WEBS-2190

- Fan-less small and exquisite design

- Fan-less solution with Quad/Dual-Core CPU

- Intel® Baytrail SoC base platform

- 1x Half-Size Mini-PCIe socket (USB + PCIe x1 signal)

- 1x Antenna hole for WiFi or 3G/GPS module to use

- OP Vibration: 5Grms/10~500Hz

- OP Shock: 50G, 11msec & IP40 Rating