Resistive vs. PCAP Touchscreens: Choosing the Right Technology for Industrial Panel PCs

Industrial Panel PCs are vital in rugged automation environments, serving as the core interface between operators and machines. On busy factory floors or fast-paced operations, responsive touchscreen monitors help streamline workflows, improve operator efficiency, and support real-time input—even in harsh conditions.

Given the central role touchscreens play in embedded systems, this blog explores

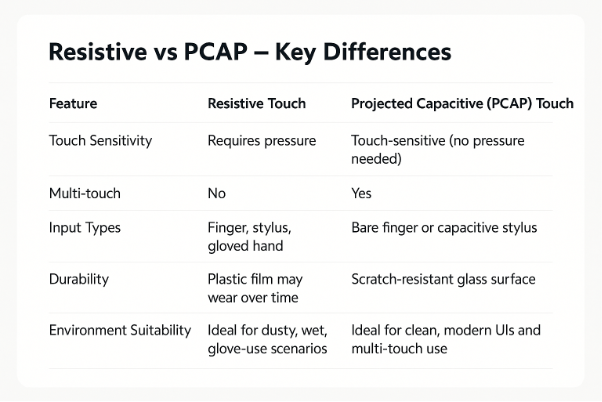

- The two advanced touchscreen technologies widely used are Resistive and PCAP (projected capacitive)

- Their mechanisms, use cases, and key differences

- How to choose the right option for your industrial application

Let’s dive in!

Discover the Leading Touchscreen Technologies

To make an informed decision, it’s important to understand how each touchscreen technology works, their structure, and how they respond to user interaction in industrial settings.

How Do Resistive Touchscreens Work?

Here is a step-by-step breakdown of the resistive touchscreen’s functionality:

Input:

Resistive touchscreens consist of two transparent conductive layers (usually Indium Tin Oxide-coated). The top layer is flexible and separated from the bottom layer by spacer dots. When pressure is applied (via finger, gloved hand, or stylus), the top layer bends and touches the bottom layer, triggering the touch event.

No Input:

To prevent false triggers, the layers remain separated until intentional pressure is applied. This makes resistive screens ideal in environments where gloves, dirt, or tools are frequently used.

Touch Response:

The touchscreen controller measures voltage changes between the two layers to determine the exact coordinates of the touch. These signals are then converted into actions on the display.

Best for: Industrial environments with gloves, high dust, moisture, or rough usage.

What Is the Alternative to Resistive Touchscreens? Understanding PCAP

Projected Capacitive (PCAP) touchscreens are the advanced alternative to resistive screens and are commonly used in smartphones, tablets, and increasingly in industrial HMI systems.

Structure:

PCAP screens have a glass surface embedded with a matrix of conductive electrodes arranged in X and Y patterns. Unlike resistive touch, PCAP does not require physical pressure—just the touch of a finger.

Touch Mechanism:

When a finger (or conductive stylus) approaches the screen, it distorts the electrostatic field at the point of contact. The controller measures this change to detect the exact location of the touch.

Key Benefits:

- Multi-touch support (pinch, zoom, rotate)

- High durability (glass surface is scratch and wear-resistant)

- Faster response time and better clarity (no flexible top layer)

Best for: Clean industrial environments, control rooms, or where multi-touch gestures and sleek user interfaces are needed.

Conclusion:

Choosing the right touch screen technology for industrial applications depends on your specific operational needs. Resistive touch screens are ideal for harsh environments where operators wear gloves or use styluses, offering durability and cost-efficiency. In contrast, PCAP (Projected Capacitive) touch screens deliver a sleek, modern interface with high responsiveness, perfect for clean, high-precision environments.

Understanding these differences helps you make an informed decision when selecting an Industrial Panel PC that aligns with your industry demands—whether in manufacturing, automation, logistics, or healthcare.

Need help choosing the right Industrial Panel PC?

Contact us today to explore the best-fit solution for your operational environment.